Where chevrolet made – Chevrolet, an iconic American automobile brand, has a rich history of manufacturing excellence. From its humble beginnings to its global presence, Chevrolet’s manufacturing operations have played a pivotal role in shaping the automotive industry. Embark on a journey to explore the where, why, and how of Chevrolet’s manufacturing prowess, unveiling the secrets behind the cars that have captured the hearts of generations.

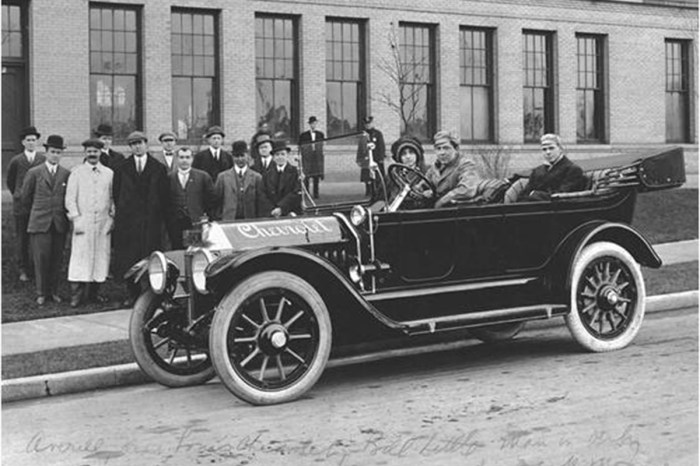

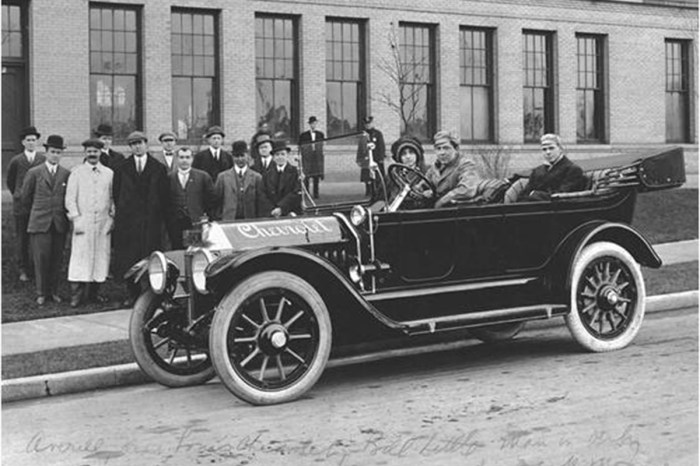

Chevrolet’s manufacturing journey began in the early 20th century, with a single plant in Flint, Michigan. Over the years, the company has expanded its operations to various locations worldwide, each plant contributing to the production of iconic Chevrolet models.

Manufacturing Plants

Chevrolet has a global manufacturing footprint with plants strategically located worldwide. Each plant plays a significant role in the production of Chevrolet vehicles, catering to the diverse needs of customers in different regions.

The company’s manufacturing facilities have a rich history and have undergone continuous upgrades and expansions to meet evolving market demands and technological advancements. These plants employ skilled workers and utilize state-of-the-art equipment to ensure the highest quality standards.

United States

- Warren Truck Assembly Plant (Michigan):Established in 1938, this plant primarily produces heavy-duty pickup trucks, including the Silverado and Sierra models. It is one of the largest truck assembly plants in the world.

- Bowling Green Assembly Plant (Kentucky):Opened in 1981, this plant is dedicated to the production of sports cars, including the Corvette. It features a state-of-the-art paint shop and assembly line designed specifically for high-performance vehicles.

- Fort Wayne Assembly Plant (Indiana):Established in 1953, this plant produces a range of SUV models, including the Equinox, Blazer, and Traverse. It has undergone several expansions and upgrades to increase production capacity.

Canada

- Oshawa Assembly Plant (Ontario):Established in 1953, this plant is one of the largest automotive assembly plants in Canada. It produces a variety of models, including the Impala, Malibu, and Equinox.

- St. Catharines Propulsion Plant (Ontario):This plant manufactures engines and transmissions for Chevrolet vehicles. It plays a crucial role in the company’s powertrain production.

Mexico

- Ramos Arizpe Assembly Plant (Coahuila):Established in 1981, this plant produces a range of models, including the Aveo, Sonic, and Trax. It is a major production hub for Chevrolet vehicles destined for the North American market.

- San Luis Potosi Assembly Plant (San Luis Potosi):Opened in 2013, this plant is dedicated to the production of the Silverado and Sierra pickup trucks. It is one of the most advanced automotive manufacturing facilities in Mexico.

Other Countries

In addition to the plants mentioned above, Chevrolet has manufacturing facilities in various other countries around the world, including Brazil, China, South Korea, and Thailand. These plants cater to the specific needs of local markets and contribute to the company’s global production capacity.

Production History

Chevrolet’s manufacturing journey spans decades, marked by technological advancements, globalization, and a commitment to innovation. The company’s production techniques have evolved significantly over the years, driven by a relentless pursuit of efficiency, quality, and customer satisfaction.

In the early days, Chevrolet’s manufacturing process was largely manual, with a focus on craftsmanship and attention to detail. As the automotive industry matured, the company embraced mass production techniques, including the use of assembly lines and standardized components. This allowed Chevrolet to increase production volume and reduce costs, making its vehicles more accessible to a broader consumer base.

Key Milestones and Innovations

- 1913:First Chevrolet assembly plant established in Flint, Michigan.

- 1924:Introduction of the first all-steel body, improving durability and safety.

- 1942-1945:Conversion to wartime production, manufacturing military vehicles and aircraft engines.

- 1953:First use of robotic welding in the automotive industry, enhancing precision and efficiency.

- 1981:Implementation of the Toyota Production System (TPS), emphasizing lean manufacturing and continuous improvement.

Impact of Globalization

Globalization has played a significant role in Chevrolet’s manufacturing strategy. In the late 20th century, the company began expanding its production facilities to other countries, including Mexico, Brazil, and China. This allowed Chevrolet to tap into new markets, reduce production costs, and respond more effectively to global demand.

Today, Chevrolet has a global manufacturing footprint with plants located in over 30 countries. This enables the company to optimize its supply chain, leverage local expertise, and meet the diverse needs of customers around the world.

Chevrolet is an American automotive brand, and their vehicles are manufactured in various locations worldwide. If you’re curious about Chevrolet’s engine history, you might wonder if they ever produced a V10 engine. To find out, check out this informative article: Did Chevrolet Make a V10? Returning to the topic of Chevrolet’s manufacturing locations, their vehicles are assembled in countries like the United States, Canada, Mexico, and China, ensuring global availability for their customers.

Regional Focus

Chevrolet’s manufacturing footprint is geographically diverse, with production facilities spread across several regions. These regions are carefully selected based on factors such as market demand, labor availability, and supply chain efficiency.

Chevrolet has been manufacturing vehicles in various locations worldwide, including the United States, Canada, and Mexico. The brand is known for its iconic models like the Camaro, which has a dedicated fan base. However, some may wonder if Chevrolet has discontinued production of the Camaro.

To find out the answer, check out this informative article: Did Chevrolet Stop Making the Camaro . Meanwhile, Chevrolet continues to produce a range of vehicles at its manufacturing facilities around the globe.

One region with a high concentration of Chevrolet manufacturing plants is North America. The United States and Mexico are home to numerous Chevrolet assembly plants, producing vehicles for both domestic and international markets. The proximity to major markets and access to skilled labor are key factors driving Chevrolet’s focus on North America.

Asia-Pacific, Where chevrolet made

- Chevrolet has a significant presence in the Asia-Pacific region, with manufacturing plants in China, South Korea, and Thailand.

- The growing demand for vehicles in these markets, coupled with favorable government policies, has made the Asia-Pacific region a strategic location for Chevrolet’s manufacturing operations.

South America

- Chevrolet maintains a strong manufacturing presence in South America, with plants in Brazil and Argentina.

- The region’s large population and expanding middle class provide a significant market for Chevrolet vehicles, making it a key focus for the company’s manufacturing operations.

Supplier Network: Where Chevrolet Made

Chevrolet has a vast supplier network that plays a crucial role in its manufacturing process. These suppliers provide various components, materials, and services that are essential for the production of Chevrolet vehicles.

Chevrolet is a widely recognized automobile manufacturer with a global presence. Its production facilities are spread across several countries, ensuring efficient distribution and meeting regional demands. If you’re curious about the scale of Chevrolet’s operations, you can find out how many employees Chevrolet has worldwide.

This information provides insights into the company’s workforce and the extent of its manufacturing capabilities. Chevrolet’s commitment to quality and innovation is evident in its vehicles, which continue to be popular choices among car enthusiasts around the world.

Key suppliers include:

- Steel suppliers:Provide high-quality steel for the production of vehicle bodies, frames, and other components.

- Aluminum suppliers:Provide lightweight aluminum for various vehicle parts, including hoods, doors, and suspension components.

- Electronics suppliers:Provide advanced electronic components, such as sensors, microcontrollers, and infotainment systems.

- Engine suppliers:Provide powerful and efficient engines that meet Chevrolet’s performance and fuel economy standards.

- Transmission suppliers:Provide robust transmissions that ensure smooth and reliable gear shifting.

Chevrolet maintains strong relationships with its suppliers, fostering collaboration and innovation. These relationships enable Chevrolet to access the latest technologies, materials, and manufacturing techniques, contributing to the overall efficiency and quality of its production process.

Quality Control

Chevrolet has implemented rigorous quality control measures throughout its manufacturing process to ensure the production of high-quality vehicles. The company employs a comprehensive system of testing and inspection procedures to verify the performance, safety, and durability of its products.

Prior to vehicle assembly, all components undergo rigorous testing and inspection. This includes testing for material strength, durability, and functionality. Suppliers are required to meet strict quality standards, and their products are subject to regular audits and inspections.

Chevrolet, the iconic American car brand, has a global presence. While Chevrolet vehicles are manufactured in various countries, including the United States, South Korea, and China, there’s a question that’s been on many minds: has chevrolet left india ? The answer is yes, Chevrolet has discontinued its operations in India as of 2017. Despite its departure from the Indian market, Chevrolet continues to manufacture and sell vehicles in other regions of the world.

Testing and Inspection Procedures

- Component Testing:Individual components are subjected to a battery of tests to assess their performance and reliability. This includes testing for strength, durability, corrosion resistance, and electrical functionality.

- Vehicle Assembly Inspection:During the assembly process, vehicles undergo multiple inspections to ensure proper fit and finish. This includes checking for body panel alignment, paint quality, and the correct installation of all components.

- Road Testing:Before vehicles are released for sale, they undergo extensive road testing to evaluate their performance, handling, and safety. These tests are conducted on a variety of road conditions, including urban, highway, and off-road environments.

Chevrolet’s commitment to quality control extends beyond the manufacturing process. The company has established a comprehensive customer feedback program to gather information on vehicle performance and identify any potential issues. This feedback is used to continuously improve the quality of Chevrolet vehicles.

Chevrolet, the iconic American car brand, has a long and storied history. From its humble beginnings in Detroit, Michigan, Chevrolet has grown to become one of the most recognizable car brands in the world. Today, Chevrolet vehicles are manufactured in a variety of countries around the globe.

But do Chevys still exist? Yes, Chevys still exist , and they continue to be a popular choice for drivers who want a reliable and affordable car. Chevrolet vehicles are still manufactured in the United States, as well as in other countries such as Canada, Mexico, and China.

Sustainability

Chevrolet has made significant strides in promoting sustainability throughout its manufacturing operations. The company has implemented various initiatives to reduce its environmental footprint, including the use of eco-friendly materials and processes. Chevrolet’s commitment to sustainability is evident in its long-term goals of minimizing waste, conserving energy, and reducing greenhouse gas emissions.

Environmental Materials and Processes

Chevrolet utilizes a range of environmentally friendly materials in its manufacturing processes. These materials include recycled plastics, lightweight metals, and sustainable fabrics. The company also employs innovative processes to minimize waste and reduce energy consumption. For instance, Chevrolet’s paint shops use a water-based system that significantly reduces volatile organic compound (VOC) emissions.

Additionally, the company has implemented energy-efficient lighting and heating systems in its manufacturing facilities.

Sustainability Goals and Initiatives

Chevrolet has set ambitious sustainability goals to guide its operations. The company aims to achieve carbon neutrality by 2040 and has committed to reducing its water usage by 15% by 2025. Chevrolet also actively supports renewable energy initiatives and has invested in solar and wind power projects.

Furthermore, the company collaborates with suppliers to promote sustainable practices throughout its supply chain.

Future Trends

The automotive industry is undergoing a period of rapid transformation, driven by technological advancements and evolving consumer demands. Chevrolet, as a leading automaker, is well-positioned to embrace these trends and shape the future of manufacturing.

One of the most significant trends is the increasing adoption of electric vehicles (EVs). EVs offer several advantages over traditional gasoline-powered vehicles, including reduced emissions, lower operating costs, and improved performance. Chevrolet has recognized the potential of EVs and has made significant investments in developing and producing a range of electric vehicles, such as the Bolt EV and the Silverado EV.

Autonomous Vehicles

Another emerging trend is the development of autonomous vehicles (AVs). AVs have the potential to revolutionize transportation by providing safer, more efficient, and more accessible mobility solutions. Chevrolet is actively exploring the development of AVs and has partnered with several technology companies to advance this technology.

Connected Vehicles

Connected vehicles are another important trend that is shaping the future of automotive manufacturing. Connected vehicles are equipped with sensors and software that allow them to communicate with other vehicles, infrastructure, and cloud-based services. This connectivity enables a wide range of new features and services, such as real-time traffic updates, remote diagnostics, and over-the-air software updates.

Chevrolet is committed to embracing these emerging trends and leveraging them to enhance its manufacturing operations. The company is investing in new technologies, such as robotics and artificial intelligence, to improve efficiency and productivity. Chevrolet is also working closely with its suppliers to ensure that they are aligned with the company’s future vision.

Last Recap

Chevrolet’s manufacturing operations have evolved significantly over the decades, driven by technological advancements, globalization, and a relentless pursuit of quality. The company’s commitment to sustainability and innovation positions it well for the future, ensuring that Chevrolet continues to produce vehicles that meet the evolving needs of drivers around the world.